Abstract:The intelligentization of modern facility agriculture mainly depends on the operation and maintenance system. The intelligentization of the operation and maintenance system is directly related to the comprehensive efficiency of greenhouse operation, and also represents the modernization of facility agriculture, which has the value of popularization and in-depth development. This paper introduces the application of intelligent operation and maintenance system in a facility agriculture base in Qingdao, analyzes its application effect, and evaluates the popularization value of the system, so as to provide information reference for relevant practitioners and expand the further in-depth study of related systems, thus improving the technical and intelligent level of facility agriculture.

Keywords: Intelligent Operation and Maintenance System; Facility Agriculture; Application

With China's rapid development, traditional agricultural production methods have been unable to meet society's demands for the quality and quantity of agricultural products. Modern facility agriculture, characterized by high yield, efficiency, and superior quality, has developed rapidly in recent years, presenting immense market potential. However, compared with developed agricultural countries or regions in the world, China's facility agriculture technology level still lags significantly, particularly in the application of agricultural IoT-based intelligent operation and maintenance systems such as agricultural sensors and machine cloud brains, where digitalization needs urgent improvement.

1. Intelligent Operation and Maintenance System for Agriculture

1.1 System Definition

The intelligent operation and maintenance system for agriculture is an emerging system technology that deeply integrates IoT technology, intelligent management technology, and various agricultural processes such as planting, storage, processing, transportation, traceability, and consumption. Through the integration of "system+hardware", the agricultural intelligent operation and maintenance system uses the key technologies of the Internet of Things, such as sensing technology, transmission technology, processing technology and common technology, to comprehensively solve the multi-interactive problems such as agricultural individual identification, situational awareness, heterogeneous equipment networking, multi-source heterogeneous data processing, knowledge discovery and decision support.

1.2 Technical Route

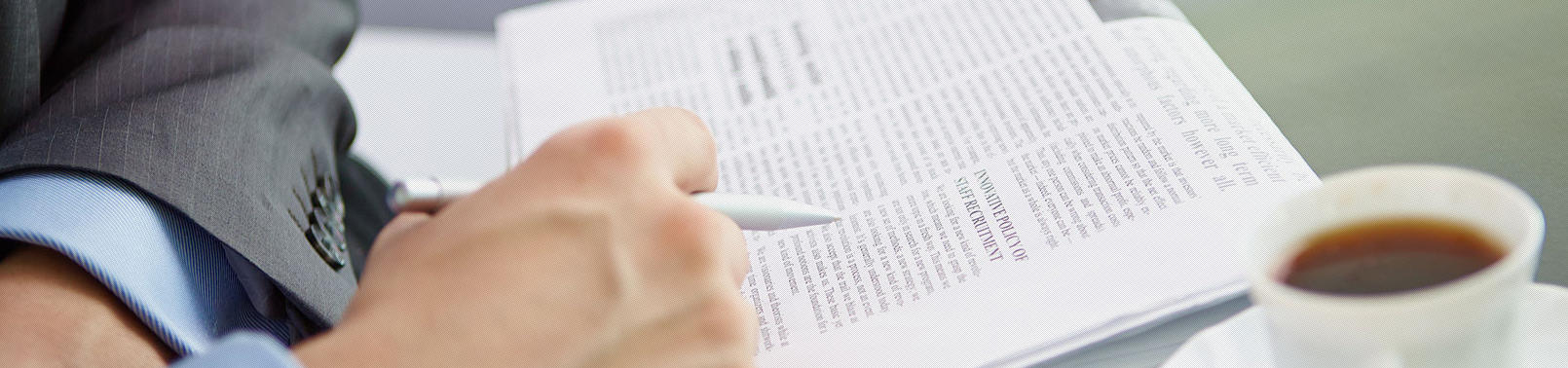

Usually, the structure of agricultural management system is mainly composed of perception, network and platform. On this basis, enterprises can expand more logical layers according to agricultural types and business needs. The architecture of the agricultural intelligent operation and maintenance system is shown in Figure 1.

In order to meet the needs of intelligent operation and maintenance of facility agriculture, sensors such as temperature and humidity sensor, carbon dioxide sensor, illumination sensor, current sensor, water flow sensor, carbon dioxide flow sensor, natural gas flow sensor, weight pressure sensor, EC sensor and pH sensor can be customized, and enterprises with large demand can research and develop sensors, and get through the underlying data transmission protocol to ensure the stable transmission and capture of data.

1.3 Development Significance

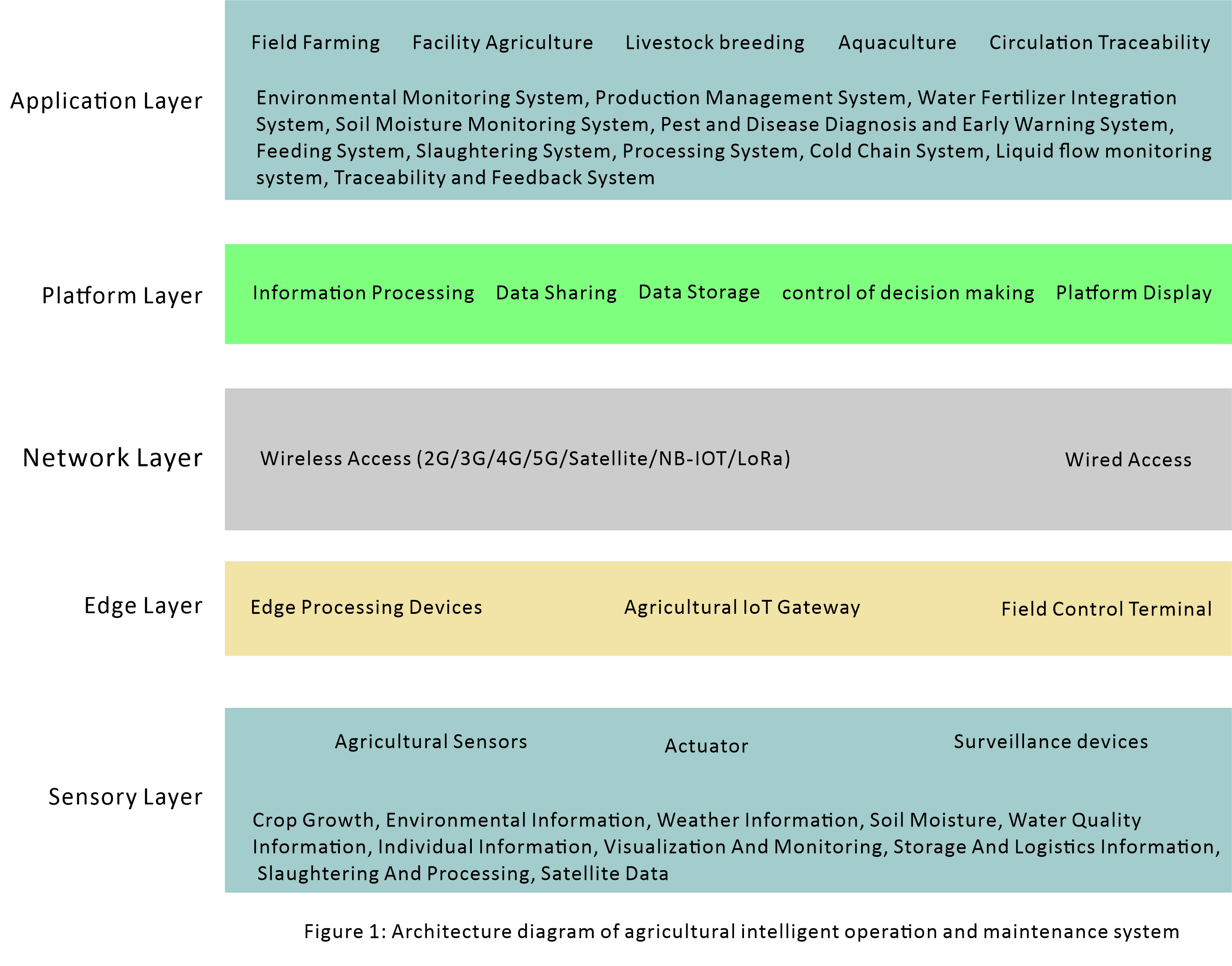

The intelligent operation and maintenance system uses intelligent sensing technology, information transmission technology and intelligent processing technology through the agricultural Internet of Things to conduct real-time monitoring and remote control of all links in agricultural activities, promote the intelligent informationization of agricultural production, management and strategic decision, and realize the high efficiency, intensification, scale and standardization of agricultural production. Finally, the vertical connection of all links in crop production and the horizontal connection of all links in the whole agricultural industry chain will be realized. Create a circular economy ecology with planting technology system, agricultural brain platform, agricultural food safety, agricultural products trade platform, new agricultural supply chain financial system, characteristic agricultural tourism and complementary planting and breeding (Figure 2).

2. Information monitoring of water and fertilizer integration

2.1 System Principle

The system carries out negative feedback to the water and fertilizer system by detecting the water content, EC, pH and other values of coconut bran matrix, which plays an important role in guiding irrigation accurately. According to the characteristics of different planting scenes, through the analysis and research of matrix characteristics and structure, to develop the empirical timing irrigation model, the upper and lower limit irrigation model of matrix water setting; water and fertilizer integrated information acquisition system can control irrigation model, the optimization and iteration can be carried out continuously in the production operation and maintenance process.

2.2 System Composition

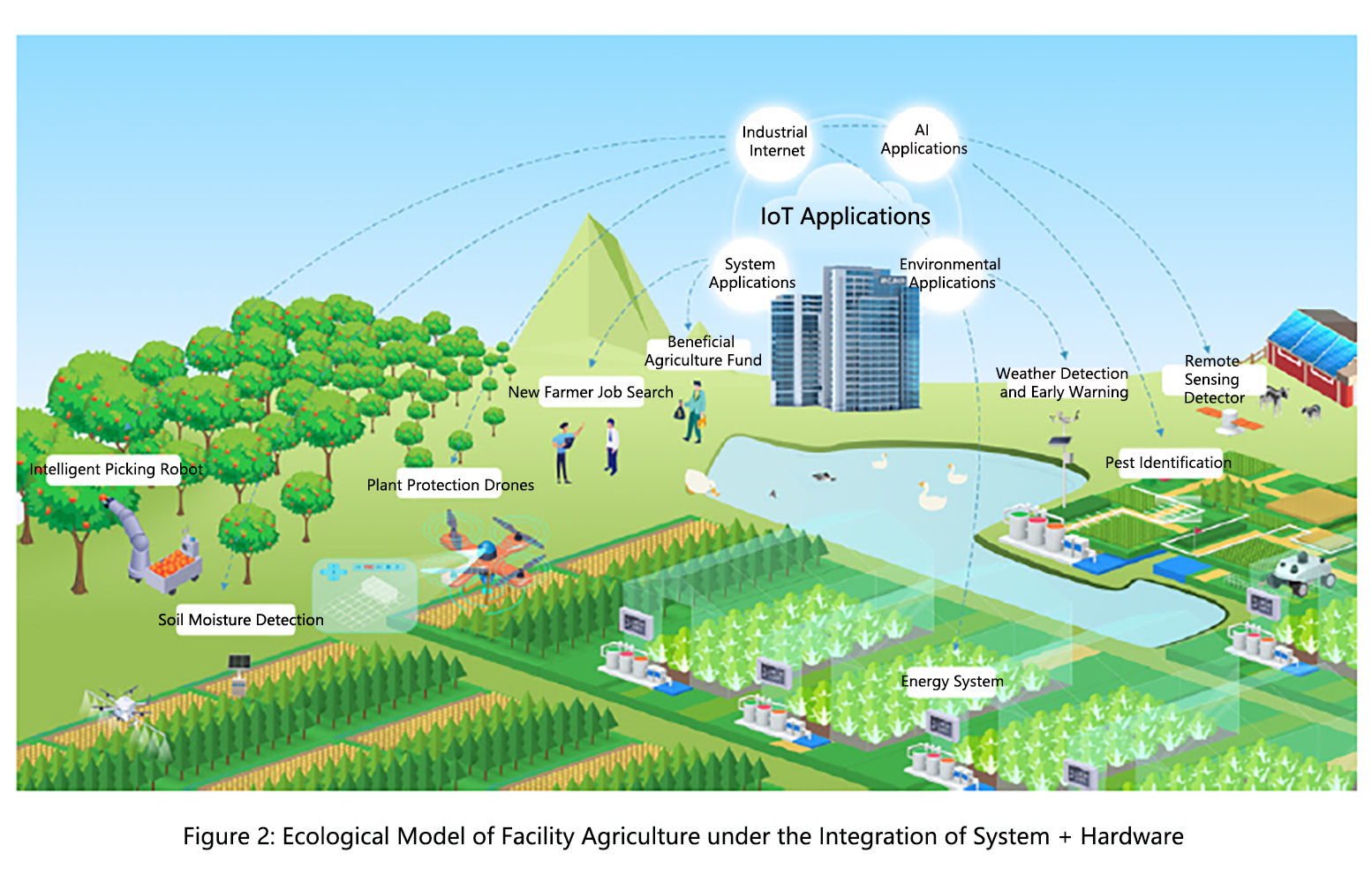

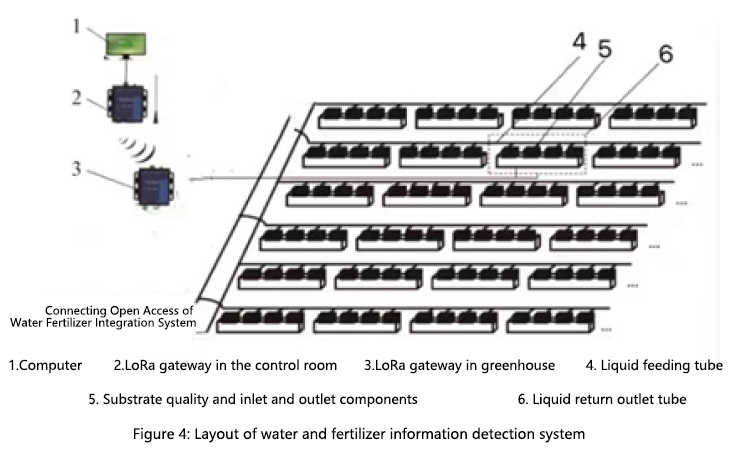

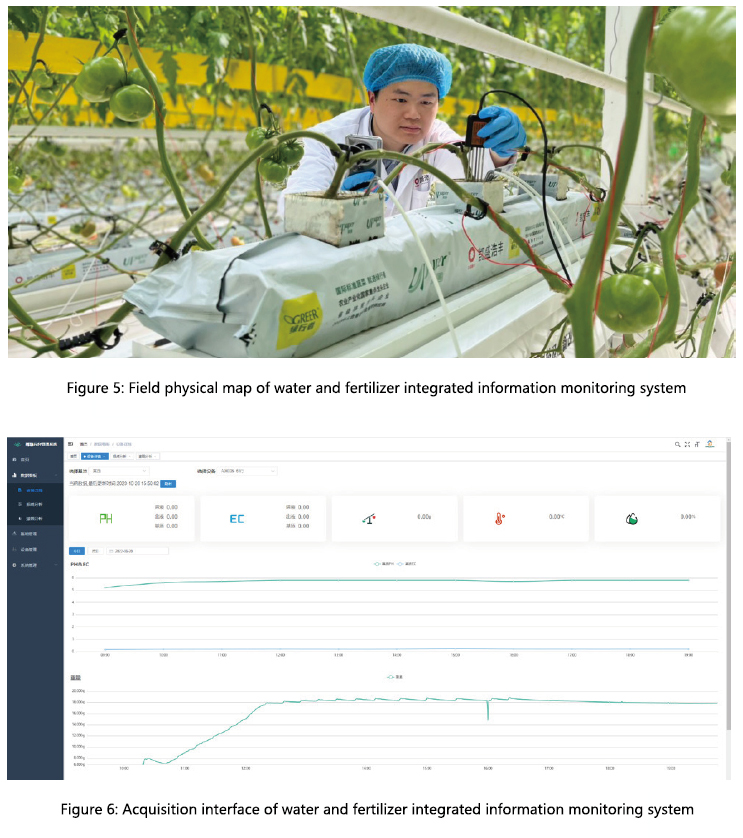

The system consists of liquid inlet collecting device, liquid return collecting device, substrate real-time monitoring device and communication component, wherein the liquid inlet collecting device consists of pH sensor, EC sensor, water pump, flowmeter and other parts; and the liquid return collecting device consists of a pressure sensor, a pH sensor, an EC sensor and other parts; The substrate real-time monitoring device consists of a liquid return collecting tray, a liquid return filter screen, a pressure sensor, a pH sensor, an EC sensor, a temperature and humidity sensor and other parts. The communication module includes two LoRa modules, one in the central control room and the other in the greenhouse (Figure 3). Wired connection exists between the computer and the communication component placed in the central control room, wireless connection exists between the communication component placed in the central control room and the communication component placed in the greenhouse, and wired connection exists between the communication component in the greenhouse and the relay, substrate detection component and liquid return detection component (Figure 4).

2.3 Application Effects

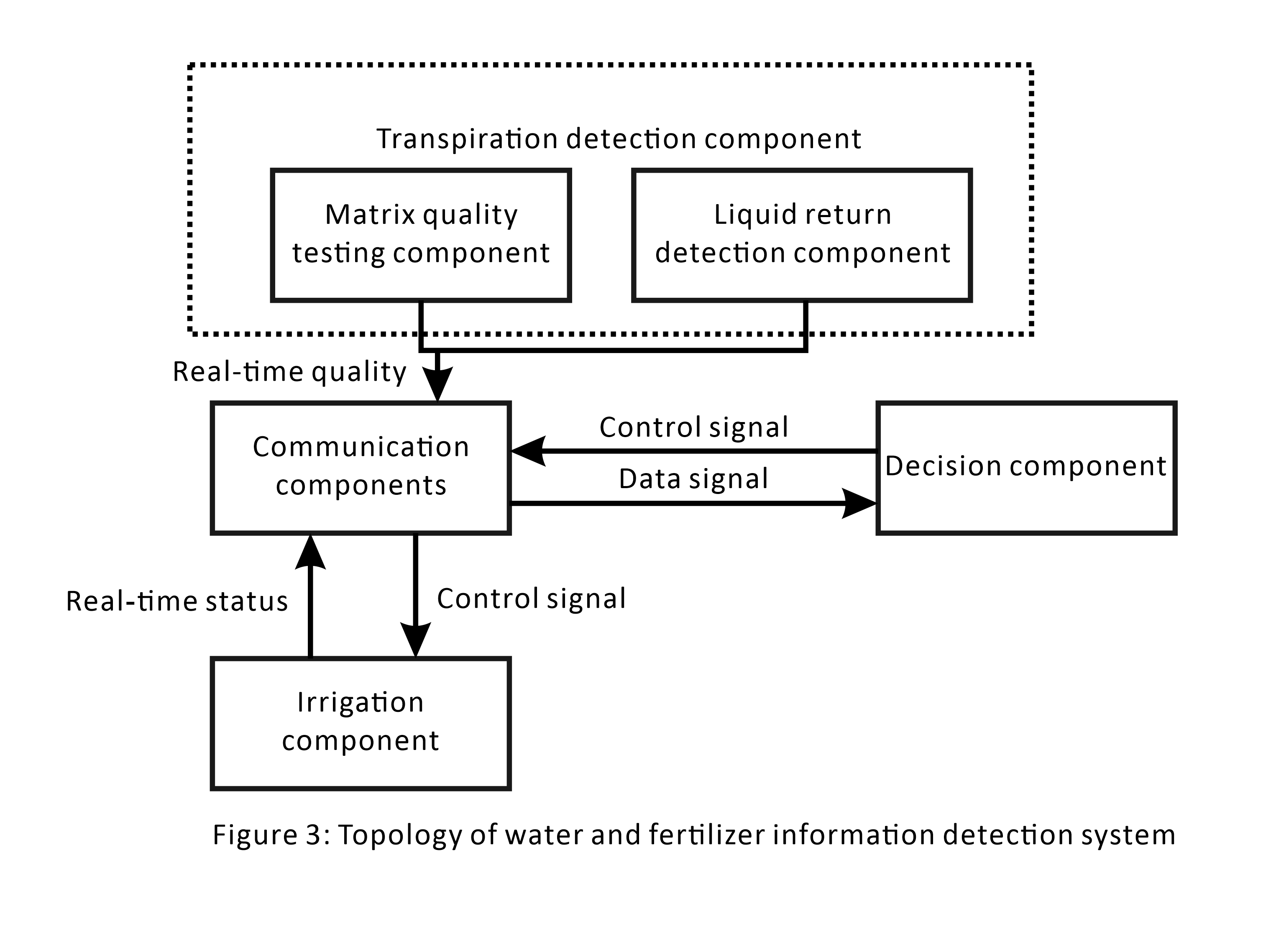

The effect of irrigation with water and fertilizer irrigation system fed back by this monitoring system is compared with that of irrigation system provided by suppliers alone. Compared with the latter, the average irrigation per tomato plant with this monitoring system is reduced by 8.7% per day, and the return liquid volume is reduced by 18%, and the EC value of the return liquid is basically the same, which shows that more nutrient solution is used by crops when this monitoring system is used for irrigation according to the law of nutrient solution absorption by crops. Using this intelligent irrigation system can reduce the irrigation amount by 29% and the liquid return by 53% on average compared with the empirical timed irrigation (Figure 5 ~ 6).

3. IoT-Based Environmental Control System

Facing the demand of accurate control of large-scale dynamic spectral nodes in plant factories, the fusion Internet of Things technology is introduced to solve the problems of large-scale and heterogeneous node acquisition and accurate control of light environment of plant. Intelligent lighting control system in plant factory takes intelligent LED lighting fixtures as the carrier, and adopts WF-IOT big data fusion Internet of Things technology to build a large-scale decentralized terminal network supporting data acquisition, transmission and control. The system can be freely grouped according to production requirements, and the light intensity of plant lighting fixtures can be continuously adjusted in real time according to different lighting conditions and plant growth needs, so as to realize accurate control of supplementary light intensity and supplementary light quantity (Figure 7). Through the peripheral network, the dynamic collection and transmission of sensing data such as environment and illumination can be realized, and at the same time, the online monitoring of energy consumption can be realized, and the energy consumption of supplementary light in each growth area can be grasped in real time.

The system realizes the fine management of plants by collecting the data of greenhouse internal and external control, and completes the product development of "plant management model". Through the sensors of current, CO2, natural gas and water, the monitoring data collection of "energy system" is realized. Using robot vision technology, through the data of fruit color, fruit number, fruit stem size, leaves, stems and so on, the whole process of crop growth data is monitored and recognized (Figure 8).

4. Promotional Value

Agricultural intelligent operation and maintenance system, using the advantages of industrial Internet platform, one investment, many times of service use, using the sharing concept of industrial Internet, promotes the construction of Internet of Things in facility agriculture at low cost and high efficiency, and improves the intelligent and green level of facility agriculture. Taking a project applying the system in Laixi City, Qingdao as an example, the comprehensive utilization rate of fertilizer can reach over 90%, which is three times that of traditional soil cultivation. There is no production sewage discharge in the whole process, which saves 95% water compared with field cultivation and reduces the pollution of fertilizer to soil. Through the detection of CO2 in greenhouse by this system, the environmental factors such as temperature and illumination inside and outside the greenhouse are comprehensively analyzed, and the supply of CO2 is regulated in real time, which not only meets the needs of plants, but also avoids waste, effectively strengthens crop photosynthesis, accelerates carbohydrate accumulation, increases yield per unit area and improves vegetable quality. The whole set of operation and maintenance management system has realized the automatic operation of greenhouse environment control facilities, the automatic and accurate operation of all-weather equipment, reduced the energy cost by 10% and the manual operation cost by 60%, and at the same time, it can make protective responses such as closing the window in the first time against adverse weather such as strong wind, rain and snow, effectively avoiding the loss of greenhouse itself and crops in the greenhouse in the face of sudden bad weather.

5. Conclusion

The modern development of facility agriculture can not be separated from the blessing of agricultural intelligent management system. Only the corresponding management system has stronger perception, analysis and decision-making ability can keep moving forward on the road of modernization. Agricultural intelligent management system greatly reduces the shortcomings of artificial management and promotes the intelligent informationization of agricultural production, management and strategic decision. With the increase of the input and the continuous enrichment of the use scenarios of the system, its data model needs to be updated and iterated constantly on the basis of more data, becoming more intelligent, and comprehensively improving the intelligent degree of modern facility agriculture.

END

[citation information]

Original author Sha Bifeng, Zhang Zheng, etl. Greenhouse Horticulture Agricultural Engineering Technology April 19, 2024 10:47 Beijing

Post time: Sep-13-2024