Li Jianming, Sun Guotao, etc.Greenhouse horticultural agricultural engineering technology2022-11-21 17:42 Published in Beijing

In recent years, the greenhouse industry has been vigorously developed. The development of greenhouse not only improves the land utilization rate and the output rate of agricultural products, but also solves the supply problem of fruits and vegetables in off-season. However, the greenhouse has also encountered unprecedented challenges. The original facilities, heating methods and structural forms have produced resistance to the environment and development. New materials and new designs are urgently needed to change the greenhouse structure, and new energy sources are urgently needed to achieve the purposes of energy conservation and environmental protection, and increase production and income.

This article discusses the theme of “new energy, new materials, new design to help the new revolution of greenhouse”, including the research and innovation of solar energy, biomass energy, geothermal energy and other new energy sources in greenhouse, the research and application of new materials for covering, thermal insulation, walls and other equipment, and the future prospect and thinking of new energy, new materials and new design to help the greenhouse reform, so as to provide reference for the industry.

Developing facility agriculture is the political requirement and inevitable choice to implement the spirit of the important instructions and the central government’s decision-making. In 2020, the total area of protected agriculture in China will be 2.8 million hm2, and the output value will exceed 1 trillion yuan. It is an important way to improve greenhouse production capacity to improve greenhouse lighting and thermal insulation performance through new energy, new materials and new greenhouse design. There are many disadvantages in traditional greenhouse production, such as coal, fuel oil and other energy sources used for heating and heating in traditional greenhouses, resulting in a large amount of dioxide gas, which seriously pollutes the environment, while natural gas, electric energy and other energy sources increase the operating cost of greenhouses. Traditional heat storage materials for greenhouse walls are mostly clay and bricks, which consume a lot and cause serious damage to land resources. The land use efficiency of traditional solar greenhouse with earth wall is only 40% ~ 50%, and the ordinary greenhouse has poor heat storage capacity, so it can’t live through the winter to produce warm vegetables in northern China. Therefore, the core of promoting greenhouse change, or basic research lies in the greenhouse design, research and development of new materials and new energy. This article will focus on the research and innovation of new energy sources in greenhouse, summarize the research status of new energy sources such as solar energy, biomass energy, geothermal energy, wind energy and new transparent covering materials, thermal insulation materials and wall materials in greenhouse, analyze the application of new energy and new materials in the construction of new greenhouse, and look forward to their role in the future development and transformation of greenhouse.

Research and Innovation of New Energy Greenhouse

The green new energy with the greatest agricultural utilization potential includes solar energy, geothermal energy and biomass energy, or comprehensive utilization of a variety of new energy sources, so as to achieve efficient use of energy by learning from each other’s strong points.

solar energy/power

Solar energy technology is a low-carbon, efficient and sustainable energy supply mode, and it is an important component of China’s strategic emerging industries. It will become an inevitable choice for the transformation and upgrading of China’s energy structure in the future. From the point of view of energy utilization, the greenhouse itself is a facility structure for solar energy utilization. Through the greenhouse effect, the solar energy is gathered indoors, the temperature of the greenhouse is raised, and the needed heat for crop growth is provided. The main energy source of photosynthesis of greenhouse plants is direct sunlight, which is the direct utilization of solar energy.

01 Photovoltaic power generation to generate heat

Photovoltaic power generation is a technology that directly converts light energy into electric energy based on photovoltaic effect. The key element of this technology is solar cell. When solar energy shines on the array of solar panels in series or in parallel, semiconductor components directly convert solar radiation energy into electric energy. Photovoltaic technology can directly convert light energy into electric energy, store electricity through batteries, and heat the greenhouse at night, but its high cost restricts its further development. The research group developed a photovoltaic graphene heating device, which consists of flexible photovoltaic panels, an all-in-one reverse control machine, a storage battery and a graphene heating rod. According to the length of the planting line, the graphene heating rod is buried under the substrate bag. During the day, the photovoltaic panels absorb solar radiation to generate electricity and store it in the storage battery, and then the electricity is released at night for the graphene heating rod. In the actual measurement, the temperature control mode of starting at 17℃ and closing at 19℃ is adopted. Running at night (20:00-08:00 on the second day) for 8 hours, the energy consumption of heating a single row of plants is 1.24 kW·h, and the average temperature of the substrate bag at night is 19.2℃, which is 3.5 ~ 5.3℃ higher than that of the control. This heating method combined withphotovoltaic power generation solves the problems of high energy consumption and high pollution in greenhouse heating in winter.

02 photothermal conversion and utilization

Solar photothermal conversion refers to the use of a special sunlight collection surface made of photothermal conversion materials to collect and absorb as much solar energy radiated onto it as possible and convert it into heat energy. Compared with solar photovoltaic applications, solar photothermal applications increase the absorption of near-infrared band, so it has higher energy utilization efficiency of sunlight, lower cost and mature technology, and is the most widely used way of solar energy utilization.

The most mature technology of photothermal conversion and utilization in China is the solar collector, the core component of which is the heat-absorbing plate core with selective absorption coating, which can convert the solar radiation energy passing through the cover plate into heat energy and transmit it to the heat-absorbing working medium. Solar collectors can be divided into two categories according to whether there is a vacuum space in the collector or not: flat solar collectors and vacuum tube solar collectors; concentrating solar collectors and non-concentrating solar collectors according to whether the solar radiation at the daylighting port changes direction; and liquid solar collectors and air solar collectors according to the type of heat transfer working medium.

Solar energy utilization in greenhouse is mainly carried out through various types of solar collectors. Ibn Zor University in Morocco has developed an active solar energy heating system (ASHS) for greenhouse warming, which can increase the total tomato production by 55% in winter. China Agricultural University has designed and developed a set of surface cooler-fan collecting and discharging system, with a heat collection capacity of 390.6~693.0 MJ, and put forward the idea of separating the heat collection process from the heat storage process by heat pump. The University of Bari in Italy has developed a greenhouse polygeneration heating system, which consists of a solar energy system and an air-water heat pump, and can increase the air temperature by 3.6% and the soil temperature by 92%. The research group has developed a kind of active solar heat collection equipment with variable inclination angle for solar greenhouse, and a supporting heat storage device for greenhouse water body across the weather. Active solar heat collection technology with variable inclination breaks through the limitations of traditional greenhouse heat collection equipment, such as limited heat collection capacity, shading and occupation of cultivated land. By using the special greenhouse structure of solar greenhouse, the non-planting space of greenhouse is fully utilized, which greatly improves the utilization efficiency of greenhouse space. Under typical sunny working conditions, the active solar heat collection system with variable inclination reaches 1.9 MJ/(m2h), the energy utilization efficiency reaches 85.1% and the energy saving rate is 77%. In the greenhouse heat storage technology, the multi-phase change heat storage structure is set, the heat storage capacity of the heat storage device is increased, and the slow release of heat from the device is realized, so as to realize the efficient use of the heat collected by the greenhouse solar heat collection equipment.

biomass energy

A new facility structure is built by combining the biomass heat-producing device with the greenhouse, and the biomass raw materials such as pig manure, mushroom residue and straw are composted to brew heat, and the generated heat energy is directly supplied to the greenhouse [5]. Compared with the greenhouse without biomass fermentation heating tank, the heating greenhouse can effectively increase the ground temperature in the greenhouse and maintain the proper temperature of the roots of crops cultivated in the soil in the normal climate in winter. Taking a single-layer asymmetric thermal insulation greenhouse with a span of 17m and a length of 30m as an example, adding 8m of agricultural waste (tomato straw and pig manure mixed) into the indoor fermentation tank for natural fermentation without turning over the pile can increase the average daily temperature of the greenhouse by 4.2℃ in winter, and the average daily minimum temperature can reach 4.6℃.

Energy utilization of biomass controlled fermentation is a fermentation method that uses instruments and equipment to control the fermentation process in order to quickly obtain and efficiently utilize biomass heat energy and CO2 gas fertilizer, among which ventilation and moisture are the key factors to regulate the fermentation heat and gas production of biomass. Under ventilated conditions, aerobic microorganisms in the fermentation heap use oxygen for life activities, and part of the generated energy is used for their own life activities, and part of the energy is released into the environment as heat energy, which is beneficial to the temperature rise of the environment. Water takes part in the whole fermentation process, providing necessary soluble nutrients for microbial activities, and at the same time releasing the heat of the heap in the form of steam through water, so as to reduce the temperature of the heap, prolong the life of microorganisms and increase the bulk temperature of the heap. Installing straw leaching device in fermentation tank can increase indoor temperature by 3 ~ 5℃ in winter, strengthen plant photosynthesis and increase tomato yield by 29.6%.

Geothermal energy

China is rich in geothermal resources. At present, the most common way for agricultural facilities to utilize geothermal energy is to use ground source heat pump, which can transfer from low-grade heat energy to high-grade heat energy by inputting a small amount of high-grade energy(such as electric energy). Different from the traditional greenhouse heating measures, ground source heat pump heating can not only achieve significant heating effect, but also have the ability to cool the greenhouse and reduce the humidity in the greenhouse. The application research of ground-source heat pump in the field of housing construction is mature. The core part that affects the heating and cooling capacity of ground-source heat pump is the underground heat exchange module, which mainly includes buried pipes, underground wells, etc. How to design an underground heat exchange system with a balanced cost and effect has always been the research focus of this part. At the same time, the change of the temperature of underground soil layer in the application of ground source heat pump also affects the use effect of heat pump system. Using the ground source heat pump to cool the greenhouse in summer and store the heat energy in the deep soil layer can alleviate the temperature drop of the underground soil layer and improve the heat production efficiency of the ground source heat pump in winter.

At present, in the research of the performance and efficiency of ground source heat pump, through the actual experimental data, a numerical model is established with software such as TOUGH2 and TRNSYS, and it is concluded that the heating performance and coefficient of performance (COP) of ground source heat pump can reach 3.0 ~ 4.5, which has a good cooling and heating effect. In the research of the operation strategy of the heat pump system, Fu Yunzhun and others found that compared with the load side flow, the ground source side flow has a greater impact on the performance of the unit and the heat transfer performance of the buried pipe. Under the condition of flow setting, the maximum COP value of the unit can reach 4.17 by adopting the operation scheme of operating for 2 hours and stopping for 2 hours; Shi Huixian et. adopted an intermittent operation mode of water storage cooling system. In summer, when the temperature is high, the COP of the whole energy supply system can reach 3.80.

Deep soil heat storage technology in greenhouse

Deep soil heat storage in greenhouse is also called “heat storage bank” in greenhouse. Cold damage in winter and high temperature in summer are the main obstacles to greenhouse production. Based on the strong heat storage capacity of deep soil, the research group designed a greenhouse underground deep heat storage device. The device is a double-layer parallel heat transfer pipeline buried at the depth of 1.5~2.5m underground in the greenhouse, with an air inlet at the top of the greenhouse and an air outlet on the ground. When the temperature in the greenhouse is high, the indoor air is forcibly pumped into the ground by a fan to realize heat storage and temperature reduction. When the temperature of the greenhouse is low, heat is extracted from the soil to warm the greenhouse. The production and application results show that the device can increase the greenhouse temperature by 2.3℃ in winter night, reduce the indoor temperature by 2.6℃ in summer day, and increase the tomato yield by 1500kg in 667 m2. The device makes full use of the characteristics of “warm in winter and cool in summer” and “constant temperature” of deep underground soil, provides an “energy access bank” for the greenhouse, and continuously completes the auxiliary functions of greenhouse cooling and heating.

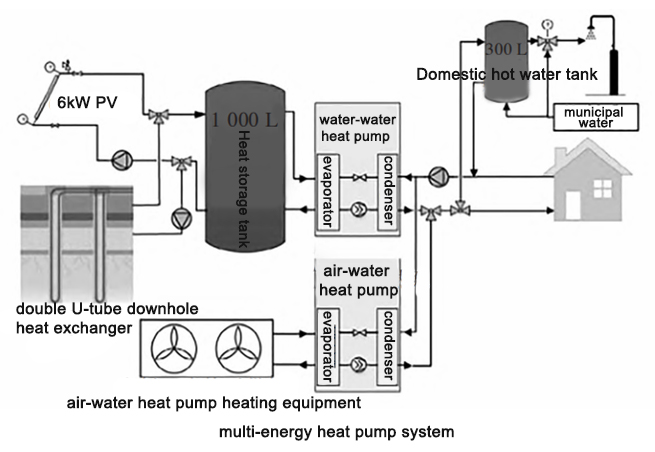

Multi-energy coordination

Using two or more energy types to heat the greenhouse can effectively make up for the disadvantages of single energy type, and give play to the superposition effect of “one plus one is greater than two”. The complementary cooperation between geothermal energy and solar energy is a research hotspot of new energy utilization in agricultural production in recent years. Emmi et. studied a multi-source energy system (Figure 1), which is equipped with a photovoltaic-thermal hybrid solar collector. Compared with the common air-water heat pump system, the energy efficiency of the multi-source energy system is improved by 16%~25%. Zheng et. developed a new type of coupled heat storage system of solar energy and ground source heat pump. The solar collector system can realize high-quality seasonal storage of heating, that is, high-quality heating in winter and high-quality cooling in summer. The buried tube heat exchanger and intermittent heat storage tank can all run well in the system, and the COP value of the system can reach 6.96.

Combined with solar energy, it aims to reduce the consumption of commercial power and enhance the stability of solar power supply in greenhouse. Wan Ya et. put forward a new intelligent control technology scheme of combining solar power generation with commercial power for greenhouse heating, which can make use of photovoltaic power when there is light, and turn it into commercial power when there is no light, greatly reducing the load power shortage rate, and reducing the economic cost without using batteries.

Solar energy, biomass energy and electric energy can jointly heat greenhouses, which can also achieve high heating efficiency. Zhang Liangrui and others combined solar vacuum tube heat collection with valley electricity heat storage water tank. The greenhouse heating system has good thermal comfort, and the average heating efficiency of the system is 68.70%. The electric heat storage water tank is a biomass heating water storage device with electric heating. The lowest temperature of water inlet at the heating end is set, and the operation strategy of the system is determined according to the water storage temperature of the solar heat collection part and the biomass heat storage part, so as to achieve stable heating temperature at the heating end and save electric energy and biomass energy materials to the maximum extent.

Innovative Research and Application of New Greenhouse Materials

With the expansion of greenhouse area, the application disadvantages of traditional greenhouse materials such as bricks and soil are increasingly revealed. Therefore, in order to further improve the thermal performance of greenhouse and meet the development needs of modern greenhouse, there are many researches and applications of new transparent covering materials, thermal insulation materials and wall materials.

Research and application of new transparent covering materials

The types of transparent covering materials for greenhouse mainly include plastic film, glass, solar panel and photovoltaic panel, among which plastic film has the largest application area. The traditional greenhouse PE film has the defects of short service life, non-degradation and single function. At present, a variety of new functional films have been developed by adding functional reagents or coatings.

Light conversion film: The light conversion film changes the optical properties of the film by using light conversion agents such as rare earth and nano materials, and can convert the ultraviolet light region into red orange light and blue violet light required by plant photosynthesis, thus increasing crop yield and reducing the damage of ultraviolet light to crops and greenhouse films in plastic greenhouses. For example, the wide-band purple-to-red greenhouse film with VTR-660 light conversion agent can significantly improve the infrared transmittance when applied in greenhouse, and compared with the control greenhouse, the tomato yield per hectare, vitamin C and lycopene content are significantly increased by 25.71%, 11.11% and 33.04% respectively. However, at present, the service life, degradability and cost of the new light conversion film still need to be studied.

Scattered glass: Scattered glass in greenhouse is a special pattern and anti-reflection technology on the surface of glass, which can maximize the sunlight into scattered light and enter the greenhouse, improve the photosynthesis efficiency of crops and increase the crop yield. Scattering glass turns the light entering the greenhouse into scattered light through special patterns, and the scattered light can be more evenly irradiated into the greenhouse, eliminating the shadow influence of the skeleton on the greenhouse. Compared with ordinary float glass and ultra-white float glass, the standard of light transmittance of scattering glass is 91.5%, and that of ordinary float glass is 88%. For every 1% increase in light transmittance inside the greenhouse, the yield can be increased by about 3%, and the soluble sugar and vitamin C in fruits and vegetables have increased. Scattering glass in greenhouse is coated first and then tempered, and the self-explosion rate is higher than the national standard, reaching 2‰.

Research and Application of New Thermal Insulation Materials

The traditional thermal insulation materials in greenhouse mainly include straw mat, paper quilt, needled felt thermal insulation quilt, etc., which are mainly used for internal and external thermal insulation of roofs, wall insulation and thermal insulation of some heat storage and heat collection devices. Most of them have the defect of losing thermal insulation performance due to internal moisture after long-term use. Therefore, there are many applications of new high thermal insulation materials, among which the new thermal insulation quilt, heat storage and heat collection devices are the research focus.

New thermal insulation materials are usually made by processing and compounding surface waterproof and aging-resistant materials such as woven film and coated felt with fluffy thermal insulation materials such as spray-coated cotton, miscellaneous cashmere and pearl cotton. A woven film spray-coated cotton thermal insulation quilt was tested in Northeast China. It was found that adding 500g spray-coated cotton was equivalent to the thermal insulation performance of 4500g black felt thermal insulation quilt in the market. Under the same conditions, the thermal insulation performance of 700g spray-coated cotton was improved by 1~2℃ compared with that of 500g spray-coated cotton thermal insulation quilt. At the same time, other studies also found that compared with the commonly used thermal insulation quilts in the market, the thermal insulation effect of spray-coated cotton and miscellaneous cashmere thermal insulation quilts is better, with the thermal insulation rates of 84.0% and 83.3%respectively. When the coldest outdoor temperature is -24.4℃, the indoor temperature can reach 5.4 and 4.2℃ respectively. Compared with the single straw blanket insulation quilt, the new composite insulation quilt has the advantages of light weight, high insulation rate, strong waterproof and aging resistance, and can be used as a new type of high-efficiency insulation material for solar greenhouses.

At the same time, according to the research of thermal insulation materials for greenhouse heat collection and storage devices, it is also found that when the thickness is the same, multi-layer composite thermal insulation materials have better thermal insulation performance than single materials. Professor Li Jianming’s team from Northwest A&F University designed and screened 22 kinds of thermal insulation materials of greenhouse water storage devices, such as vacuum board, aerogel and rubber cotton, and measured their thermal properties. The results showed that 80mm thermal insulation coating+aerogel+rubber-plastic thermal insulation cotton composite insulation material could reduce the heat dissipation by 0.367MJ per unit time compared with 80mm rubber-plastic cotton, and its heat transfer coefficient was 0.283W/(m2·k) when the thickness of the insulation combination was 100mm.

Phase change material is one of the hot spots in greenhouse materials research. Northwest A&F University has developed two kinds of phase change material storage devices: one is a storage box made of black polyethylene, which has a size of 50cm×30cm×14cm (length×height×thickness) and is filled with phase change materials, so that it can store heat and release heat; Secondly, a new type of phase-change wallboard is developed. The phase-change wallboard consists of phase-change material, aluminum plate, aluminum-plastic plate and aluminum alloy. The phase-change material is located at the most central position of the wallboard, and its specification is 200mm×200mm×50mm. It is a powdery solid before and after phase change, and there is no phenomenon of melting or flowing. The four walls of the phase-change material are aluminum plate and aluminum-plastic plate, respectively. This device can realize the functions of mainly storing heat during the day and mainly releasing heat at night.

Therefore, there are some problems in the application of single thermal insulation material, such as low thermal insulation efficiency, large heat loss, short heat storage time, etc. Therefore, using composite thermal insulation material as thermal insulation layer and indoor and outdoor thermal insulation covering layer of heat storage device can effectively improve the thermal insulation performance of greenhouse, reduce the heat loss of greenhouse, and thus achieve the effect of saving energy.

Research and Application of New Wall

As a kind of enclosure structure, the wall is an important barrier for greenhouse’s cold protection and heat preservation. According to the wall materials and structures, the development of the northern wall of greenhouse can be divided into three types: the single-layer wall made of soil, bricks, etc., and the layered northern wall made of clay bricks, block bricks, polystyrene boards, etc., with inner heat storage and outer heat insulation, and most of these walls are time-consuming and labor-intensive; Therefore, in recent years, many new types of walls have appeared, which are easy to build and suitable for quick assembly.

The emergence of new-type assembled walls promotes the rapid development of assembled greenhouses, including new-type composite walls with external waterproof and anti-aging surface materials and materials such as felt, pearl cotton, space cotton, glass cotton or recycled cotton as heat insulation layers, such as flexible assembled walls of spray-bonded cotton in Xinjiang. In addition, other studies have also reported the northern wall of assembled greenhouse with heat storage layer, such as brick-filled wheat shell mortar block in Xinjiang. Under the same external environment, when the lowest outdoor temperature is -20.8℃, the temperature in the solar greenhouse with wheat shell mortar block composite wall is 7.5℃, while the temperature in the solar greenhouse with brick-concrete wall is 3.2℃. The harvest time of tomato in brick greenhouse can be advanced by 16 days, and the yield of single greenhouse can be increased by 18.4%.

The facility team of Northwest A&F University put forward the design idea of making straw, soil, water, stone and phase change materials into thermal insulation and heat storage modules from the angle of light and simplified wall design, which promoted the application research of modular assembled wall. For example, compared with ordinary brick wall greenhouse, the average temperature in the greenhouse is 4.0℃ higher on a typical sunny day. Three kinds of inorganic phase change cement modules, which are made of phase change material (PCM) and cement, have accumulated heat of 74.5, 88.0 and 95.1 MJ/m3, and released heat of 59.8, 67.8 and 84.2 MJ/m3, respectively. They have the functions of “peak cutting” in daytime, “valley filling” at night, absorbing heat in summer and releasing heat in winter.

These new walls are assembled on site, with short construction period and long service life, which create conditions for the construction of light, simplified and quickly assembled prefabricated greenhouses, and can greatly promote the structural reform of greenhouses. However, there are some defects in this kind of wall, such as the spray-bonded cotton thermal insulation quilt wall has excellent thermal insulation performance, but lacks heat storage capacity, and the phase change building material has the problem of high use cost. In the future, the application research of assembled wall should be strengthened.

New energy, new materials and new designs help the greenhouse structure change.

The research and innovation of new energy and new materials provide the foundation for the design innovation of greenhouse. Energy-saving solar greenhouse and arch shed are the largest shed structures in China’s agricultural production, and they play an important role in agricultural production. However, with the development of China’s social economy, the shortcomings of the two kinds of facility structures are increasingly presented. First, the space of facility structures is small and the degree of mechanization is low; Second, the energy-saving solar greenhouse has good thermal insulation, but the land use is low, which is equivalent to replacing the greenhouse energy with land. Ordinary arch shed not only has small space, but also has poor thermal insulation. Although the multi-span greenhouse has large space, it has poor thermal insulation and high energy consumption. Therefore, it is imperative to research and develop the greenhouse structure suitable for China’s current social and economic level, and the research and development of new energy and new materials will help the greenhouse structure change and produce a variety of innovative greenhouse models or structures.

Innovative Research on Large-span Asymmetric Water-controlled Brewing Greenhouse

The large-span asymmetric water-controlled brewing greenhouse (patent number: ZL 201220391214.2) is based on the principle of sunlight greenhouse, changing the symmetrical structure of ordinary plastic greenhouse, increasing the southern span, increasing the lighting area of the southern roof, reducing the northern span and reducing the heat dissipation area, with a span of 18~24m and a ridge height of 6~7m. Through design innovation, the spatial structure has been significantly increased. At the same time, the problems of insufficient heat in greenhouse in winter and poor thermal insulation of common thermal insulation materials are solved by using new technology of biomass brewing heat and thermal insulation materials. The production and research results show that the large-span asymmetric water-controlled brewing greenhouse, with an average temperature of 11.7℃ on sunny days and 10.8℃ on cloudy days, can meet the demand of crop growth in winter, and the construction cost of the greenhouse is reduced by 39.6% and the land utilization rate is increased by more than 30% compared with that of the polystyrene brick wall greenhouse, which is suitable for further popularization and application in the Yellow Huaihe River Basin of China.

Assembled sunlight greenhouse

Assembled sunlight greenhouse takes columns and roof skeleton as load-bearing structure, and its wall material is mainly heat insulation enclosure, instead of bearing and passive heat storage and release. Mainly: (1) a new type of assembled wall is formed by combining various materials such as coated film or color steel plate, straw block, flexible thermal insulation quilt, mortar block, etc. (2) composite wall board made of prefabricated cement board-polystyrene board-cement board; (3) Light and simple assembly type of thermal insulation materials with active heat storage and release system and dehumidification system, such as plastic square bucket heat storage and pipeline heat storage. Using different new heat insulation materials and heat storage materials instead of traditional earth wall to build solar greenhouse has large space and small civil engineering. The experimental results show that the temperature of the greenhouse at night in winter is 4.5℃ higher than that of the traditional brick-wall greenhouse, and the thickness of the back wall is 166mm. Compared with the 600mm thick brick-wall greenhouse, the occupied area of the wall is reduced by 72%, and the cost per square meter is 334.5 yuan, which is 157.2 yuan lower than that of the brick-wall greenhouse, and the construction cost has dropped significantly. Therefore, the assembled greenhouse has the advantages of less cultivated land destruction, land saving, fast construction speed and long service life, and it is a key direction for the innovation and development of solar greenhouses at present and in the future.

Sliding sunlight greenhouse

The skateboard-assembled energy-saving solar greenhouse developed by Shenyang Agricultural University uses the back wall of the solar greenhouse to form a water circulating wall heat storage system to store heat and raise temperature, which is mainly composed of a pool (32m3), a light collecting plate (360m2), a water pump, a water pipe and a controller. The flexible thermal insulation quilt is replaced by a new lightweight rock wool colored steel plate material at the top. The research shows that this design effectively solves the problem of gables blocking light, and increases the light entry area of the greenhouse. The lighting angle of the greenhouse is 41.5°, which is nearly 16° higher than that of the control greenhouse, thus improving the lighting rate. The indoor temperature distribution is uniform, and the plants grow neatly. The greenhouse has the advantages of improving land use efficiency, flexibly designing greenhouse size and shortening construction period, which is of great significance to protecting cultivated land resources and environment.

Photovoltaic greenhouse

Agricultural greenhouse is a greenhouse that integrates solar photovoltaic power generation, intelligent temperature control and modern high-tech planting. It adopts a steel bone frame and is covered with solar photovoltaic modules to ensure the lighting requirements of photovoltaic power generation modules and the lighting requirements of the whole greenhouse. The direct current generated by solar energy directly supplements the light of agricultural greenhouses, directly supports the normal operation of greenhouse equipment, drives the irrigation of water resources, increases the greenhouse temperature and promotes the rapid growth of crops. Photovoltaic modules in this way will affect the lighting efficiency of greenhouse roof, and then affect the normal growth of greenhouse vegetables. Therefore, the rational layout of photovoltaic panels on the roof of greenhouse becomes the key point of application. Agricultural greenhouse is the product of the organic combination of sightseeing agriculture and facility gardening, and it is an innovative agricultural industry integrating photovoltaic power generation, agricultural sightseeing, agricultural crops, agricultural technology, landscape and cultural development.

Innovative design of greenhouse group with energy interaction among different types of greenhouses

Guo Wenzhong, a researcher at Beijing Academy of Agricultural and Forestry Sciences, uses the heating method of energy transfer between greenhouses to collect the remaining heat energy in one or more greenhouses to heat another or more greenhouses. This heating method realizes the transfer of greenhouse energy in time and space, improves the energy utilization efficiency of the remaining greenhouse heat energy, and reduces the total heating energy consumption. The two types of greenhouses can be different greenhouse types or the same greenhouse type for planting various crops, such as lettuce and tomato greenhouses. Heat collection methods mainly include extracting indoor air heat and directly intercepting incident radiation. Through solar energy collection, forced convection by heat exchanger and forced extraction by heat pump, the surplus heat in high-energy greenhouse was extracted for heating greenhouse.

summarize

These new solar greenhouses have the advantages of quick assembly, shortened construction period and improved land utilization rate. Therefore, it is necessary to further explore the performance of these new greenhouses in different areas, and provide the possibility for the large-scale popularization and application of new greenhouses. At the same time, it is necessary to continuously strengthen the application of new energy and new materials in greenhouses, so as to provide power for the structural reform of greenhouses.

Future prospect and thinking

Traditional greenhouses often have some disadvantages, such as high energy consumption, low land utilization rate, time-consuming and labor-consuming, poor performance, etc., which can no longer meet the production needs of modern agriculture, and are bound to be gradually eliminated. Therefore, it is a development trend to use new energy sources such as solar energy, biomass energy, geothermal energy and wind energy, new greenhouse application materials and new designs to promote the structural change of greenhouse. First of all, the new greenhouse driven by new energy and new materials should not only meet the needs of mechanized operation, but also save energy, land and cost. Secondly, it is necessary to constantly explore the performance of new greenhouses in different areas, so as toprovide conditions for large-scale popularization of greenhouses. In the future, we should further search for new energy and new materials suitable for greenhouse application, and find the best combination of new energy, new materials and greenhouse, so as to make it possible to build a new greenhouse with low cost, short construction period, low energy consumption and excellent performance, help the greenhouse structure change and promote the modernization development of greenhouses in China.

Although the application of new energy, new materials and new designs in greenhouse construction is an inevitable trend, there are still many problems to be studied and overcome: (1) The construction cost increases. Compared with the traditional heating with coal, natural gas or oil, the application of new energy and new materials is environmentally friendly and pollution-free, but the construction cost is significantly increased, which has a certain impact on the investment recovery of production and operation. Compared with energy utilization, the cost of new materials will be significantly increased. (2) Unstable utilization of heat energy. The biggest advantage of new energy utilization is low operating cost and low carbon dioxide emission, but the supply of energy and heat is unstable, and cloudy days become the biggest limiting factor in solar energy utilization. In the process of biomass heat production by fermentation, the effective utilization of this energy is limited by the problems of low fermentation heat energy, difficult management and control, and large storage space for raw materials transportation. (3) Technology maturity. These technologies used by new energy and new materials are advanced research and technological achievements, and their application area and scope are still quite limited. They have not passed many times, many sites and large-scale practice verification, and there are inevitably some deficiencies and technical contents that need to be improved in application. Users often deny the advancement of technology because of the minor deficiencies. (4) The technology penetration rate is low. The wide application of a scientific and technological achievement requires a certain popularity. At present, new energy, new technology and new greenhouse design technology are all in the team of scientific research centers in universities with certain innovation ability, and most technical demanders or designers still don’t know; At the same time, the popularization and application of new technologies are still quite limited because the core equipment of new technologies are patented. (5) The integration of new energy, new materials and greenhouse structure design needs to be further strengthened. Because energy, materials and greenhouse structure design belong to three different disciplines, talents with greenhouse design experience often lack research on greenhouse-related energy and materials, and vice versa; Therefore, researchers related to energy and materials research need to strengthen the investigation and understanding of the actual needs of greenhouse industry development, and structural designers should also study new materials and new energy to promote the deep integration of the three relationships, so as to achieve the goal of practical greenhouse research technology, low construction cost and good use effect. Based on the above problems, it is suggested that the state, local governments and scientific research centers should intensify technical research, carry out joint research in depth, strengthen the publicity of scientific and technological achievements, improve the popularization of achievements, and quickly realize the goal of new energy and new materials to help the new development of greenhouse industry.

Cited information

Li Jianming, Sun Guotao, Li Haojie, Li Rui, Hu Yixin. New energy, new materials and new design help the new revolution of greenhouse [J]. Vegetables, 2022,(10):1-8.

Post time: Dec-03-2022